Types Of Compressors

Screw Compressor

The original EcoCOOL® Blend is compatible with Rotary (screw) compressors provided that there is not a Coalescing Oil Separator. Coalescing Oil Separators are generally a horizontally mounted cylinder. On Rotary (screw) compressors that do not have a coalescing oil separator, Original EcoCOOL® Blend is added to the refrigeration circuit at 10% of the manufacturers stated oil charge.

The original EcoCOOL® Blend is compatible with Rotary (screw) compressors provided that there is not a Coalescing Oil Separator. Coalescing Oil Separators are generally a horizontally mounted cylinder. On Rotary (screw) compressors that do not have a coalescing oil separator, Original EcoCOOL® Blend is added to the refrigeration circuit at 10% of the manufacturers stated oil charge.

Centrifugal Compressor

Centrifugal Compressors can contain a separate oil circuit and no DX valve. In this case we add EcoCOOL®1 to the refrigerant circuit at .3 ounces per ton.

Centrifugal Compressors can contain a separate oil circuit and no DX valve. In this case we add EcoCOOL®1 to the refrigerant circuit at .3 ounces per ton.

We separately add the lubricity agent, EcoCOOL®, to the oil circuit at 2% of the manufacturers stated oil charge. It is an industry known fact that oil fouling occurs from oil intruding into the refrigerant circuit over time through leaky seals.

This makes Catalyst 1 effective in removing oil fouling. Catalyst #2 reacts as it passes through the DX valve which is non existent in these systems.

Reciprocating (Piston) Compressor

For Reciprocating Compressors that use traditional refrigerants, install original blend EcoCOOL® at a ratio of 10% of the manufacturers stated oil charge.

For systems with long refrigerant lines over 75 feet it is recommended to install 15%.

Semi-Hermetic Compressor

Semi-Hermetic compressors are housed with the motor in the same housing but the casing is a bolted type and can be repaired easily. The oil level is monitored by a sight gauge and an equal amount of oil should be removed for the amount of EcoCOOL® being installed.

Semi-Hermetic compressors are housed with the motor in the same housing but the casing is a bolted type and can be repaired easily. The oil level is monitored by a sight gauge and an equal amount of oil should be removed for the amount of EcoCOOL® being installed.

Ammonia Systems

EcoCOOL® SYNTHETIC CATALYST TECHNOLOGY FOR AMMONIA IS FOR AMMONIA DX SYSTEMS ONLY WITH PISTON TYPE COMPRESSORS. EcoCOOL® cannot be used in non DX, or screw, or centrifugal compressor systems. EcoCOOL® Ammonia Blend is installed at 5% of the manufacturers stated oil charge. It is recommended to remove 5% of the existing oil charge before the EcoCOOL® installation. EcoCOOL® Ammonia Blend has been successfully used in reciprocating compressor systems. As in all systems, it is critical to confirm that there is no coalescing oil separator. Screw compressors are common with ammonia refrigerant, and coalescing oil separators are common on screw compressors.

Hermetically Sealed Scroll Compressor

Original Blend EcoCOOL® is installed in the low pressure service port (Schrader valve). We install EcoCOOL® in scroll type compressors at a ratio of 10% of the manufacturer’s stated oil charge.

Original Blend EcoCOOL® is installed in the low pressure service port (Schrader valve). We install EcoCOOL® in scroll type compressors at a ratio of 10% of the manufacturer’s stated oil charge.

Hermetic Compressor

Hermetic type compressors have a completely sealed housing with its motor also sealed in the same housing. It is leak proof but cannot be repaired. We do not remove any oil when installing EcoCOOL®.

Hermetic type compressors have a completely sealed housing with its motor also sealed in the same housing. It is leak proof but cannot be repaired. We do not remove any oil when installing EcoCOOL®.

Packaged Units

Typically found on roof tops, a packaged unit can have multiple compressors with sometimes various sizes. It is critical to retrieve compressor specifications from the actual compressor inside the packaged unit and not the manufacturer’s label on the outside of the unit. Scroll compressors are commonly used in packaged units. The oil charge can usually be found on the compressor label. Calculate 10% of the oil charge for scroll compressors and install EcoCOOL® in the low pressure service port. If the oil charge is not listed, a Google search with compressor make, model number, and specifications will lead to the specifications manual.

Typically found on roof tops, a packaged unit can have multiple compressors with sometimes various sizes. It is critical to retrieve compressor specifications from the actual compressor inside the packaged unit and not the manufacturer’s label on the outside of the unit. Scroll compressors are commonly used in packaged units. The oil charge can usually be found on the compressor label. Calculate 10% of the oil charge for scroll compressors and install EcoCOOL® in the low pressure service port. If the oil charge is not listed, a Google search with compressor make, model number, and specifications will lead to the specifications manual.

Split Systems

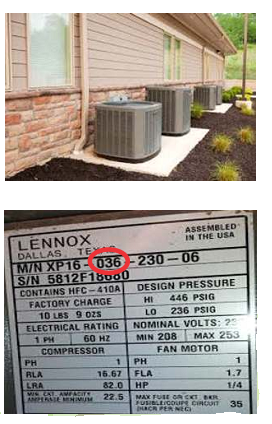

Typically found in residential and small business applications, split systems use traditional refrigerants that are all compatible with original blend EcoCOOL®. EcoCOOL® is installed at the outside condensing unit and is injected into the low pressure service port (Schrader valve). EcoCOOL® is installed in split systems at a ratio of one unit (ounce) per ton. The manufacturers label on the outside condensing unit will have a model number with the BTU’s in that model number. One ton is equal to 12,000 BTU’s. This label indicates 36,000 BTU’s which is equal to 3 tons. 3 units of EcoCOOL® is recommended for installation in this unit.

Typically found in residential and small business applications, split systems use traditional refrigerants that are all compatible with original blend EcoCOOL®. EcoCOOL® is installed at the outside condensing unit and is injected into the low pressure service port (Schrader valve). EcoCOOL® is installed in split systems at a ratio of one unit (ounce) per ton. The manufacturers label on the outside condensing unit will have a model number with the BTU’s in that model number. One ton is equal to 12,000 BTU’s. This label indicates 36,000 BTU’s which is equal to 3 tons. 3 units of EcoCOOL® is recommended for installation in this unit.